Savoie Hexapôle (unité de production) - 10 Rue Charles Montreuil - 73420 Méry

Sodeva your best in cutting buy !

Sodeva is a designer and manufacturer of all its cutting machines for the food industry, including vibrating blades. We manufacture food slicers that are composed of our own vibration-activated blades with ultrasonic or conventional technology. We install cutting lines for cheese, confectionery, pastry, industrial bakery, chocolate, sweets or meat.

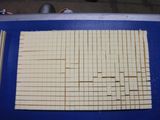

Standard cutting machines are available for all products. A custom-made or adapted slicing machine is always possible to realize. The product to be cut/sliced is tested to select the best blade and equipment. The cuts are fast, nice looking, appetizing and very precise.

Cutting of cheeses to the right weight with portioning slicer from 100 kg wheels to goat's cheese, fixed weight (with volume reconstitution) or regulated weight and pieces. We design our weighing scales in line for slicing to the nearest gram, vertical cuts, horizontal slicing or multi-station cutting of soft or hard cheese. Round or rectangular formats can be handled by the same slicer. Our vision systems can produce fixed weight cheese in wheels or lengths and place the blades between the cheese labels and produce fixed weight slices.

The cutting options and vibrations are designed to process soft, pressed, hard and semi-hard cheeses with a core in the center of the cheese wheel. The machines are versatile for all formats with one or more successive cutting stations. We favor the minimum of adjustment without tools to slice the product. Our ultrasonic Vibracut cuts Brie cheese wheels equatorially in two to allow their filling and then their cutting into points.

The pastries are cut in fresh or frozen from rectangular frames (from the mignardise to the mille feuilles), or cut in molds for round pies in line on several all speed conveyors. The high frequency ultrasound achieves a smooth and appetizing slicing without cones and moisture from the water jet by separating well the parts for an easier packaging.

We have developed the slicing of frozen bread in line to supply sandwich shops, 7000 breads or buns can be sliced per hour but also rusks, dough before cooking to the right thickness or the scarification in line to make slices of buns.

Confectionery cut by special ultrasonic blades with output in bars or cubes for nougat, fruit paste, chocolate, marshmallow or cereal bars. Our robots of small dimensions allow the programmable separation with our anti-sticking ultrasonic blades and the trimming of the products. Chocolate plates are cut into candies with a spacing allowing in-line coating, cereal bars are coated on slicers in 3x8H. Pressurized water jet cutting does not allow the spacing of the portions for coating.

Our cutter allows a programmable spacing for all in-line coating of cereal bars, fruit jellies, nougat or chocolates. Our new Chococut model spaces each candy on your paper film plates for easy coating.

For the production of cold cuts, the cutting of pâtés or pâtés croute with weight management is a classic. Various compositions to be cut including meat or vegetables (artichoke, peppers, spinach...) into products and complementary pieces for your slicer. The sonotrode is calculated to slice without sticking and at high speed the slices of pâtés in variable width.

Our technology allows to cut at high frequency with the energy of our multi-frequency generator the most complex multi-component products, meat pâté croute, terrines... The cutting precision after weighing is a few grams.

The world of industrial slicing of frozen or fresh products no longer holds any secrets for us. Indeed, our food slicers are able to operate and cut your cakes, pies, fish blocks, meats, breads, sandwiches etc. thanks to our patented micro-toothed ultrasonic blades able to cut at -18°C without breaking the cold chain, where other cutting blades on the market stall at -10°C.

Aperitif or tapas type markets requiring small cubes or sticks are now accessible with our new thin and long orientable blade, the Vibracut sonotrode, which cuts into horizontal slices and then into cubes by these patented knives. The sliced products are conveyed in line to the packaging controlled by our slicers. A technical description of the machine will give you its size and technical capacity.

Integrated cleaning systems of the Ecolab brand can be installed in our machines to meet the hygiene standards of disinfection and optimized washing. The ultrasonic blades are automatically washed according to the cycle and the type of production. This technical combination is very profitable in food processing.

Our range of high-tech machines and our manufacturing allow us to allocate a budget for each type of product at the best quality-price ratio including the best components because we are designers and manufacturers of all our machines, including the ultrasonic tuning fork.

Our installations are present all over the world, from compact portioning machines to complete lines equipped with checkweighers with feedback from the cut on the weights recorded at the end of the line. The efficiency of the use of our equipment is thus permanently controlled by minimizing the overweight and optimizing the output. Each system is adapted to the country's standards. A code allows to connect to the automaton and to check its good functioning.

A machine in production has its system adapted to the customer's specifications. The materials are mainly made of stainless steel, the welding done by our boilermakers is polished on all sides to avoid any water retention. We retain the best solutions for an optimal ultrasonic use in our manufacture with edition of a sound certificate for the equipment with plastic insulation of great thickness. The electronic and composite components are of the best quality with the choice of the best supplier.

We have registered patents and trademarks that allow us to continuously improve the use of our ultrasonic slicing processes to match your machine solution for your production and to benefit you for the best processing and transformation of your product at high speed without loss. Our generators control the ultrasound in an optimal way with settings stored in the machine for each recipe.

Our manufacturing is integrated, design office, automation, electrical wiring, boiler making, laser cutting, machining, assembly and the machine line in production is equipped with all your recipes for your peace of mind with periodic supervision by internet and connection on remote system of your ultrasonic slicer all applications.

Our ultrasonic blades and technologies allow the cutting of composite products and equip cutting robots in the automotive industry to slice carbon, textile or rubber plates.

We offer high-tech sets composed of a 20 or 35 kHz high frequency generator (for cutting, welding or screening), a transmitter and a sonotrode from 200 mm to more than one meter in length. The ultrasound is controlled and adapted to all products with a blade control system of the highest quality to cut all materials. The center of the technology is the blade, which then allows the construction of a standard or custom machine. Our patents guarantee a constantly improved manufacturing process in areas of strength that our competitors cannot reach.

Our ultrasonic sieving with rental option or our sieve cloths for all brands of sieving machines are highly appreciated for their performance... The vibrations allow us to sieve powders from 20 microns and more.

Enjoy your visit on our tabs dedicated to each product!

Ultrasonic systems (generators, transmitters, blade boosters, sieves, frames) and manufacture of all machines (design, production, boiler making, assembly, automation, tuning)

Ultrasonic sieving: ultrasonic technology associated with the vibration of the vibrating sieve to obtain a soft de-clogging and in total respect of the qualities of all powders from 20 micron cloths and efficient de-clogging, high flow rate serum separators for cheese factories (40 m3/h),

All empty mesh frames or all types of vibrating sifter models are covered in accordance with the required standards, year-round contracts are offered with security stock, we work in 2×8 hours to guarantee rapid delivery.

We have a standard range of trenchers, sifters and washing stations in stock. Our rental or trial formula with purchase option has seduced many of our customers by its simplicity and transparency, try it!